Services

Flexible Packaging Solutions and Unbeatable Quality

Plastic Bags

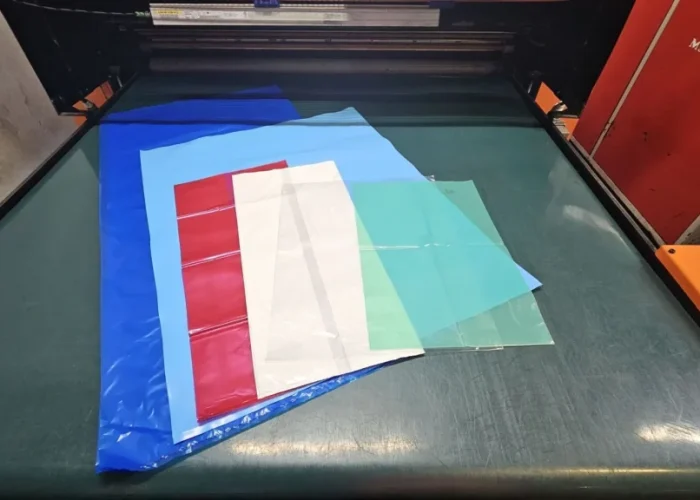

Formpack provides a diverse selection of personalised polybag solutions to suit your requirements. While most of our polybags are crafted from low-density polyethylene (LDPE), we have the capability to produce medium-density (MDPE) and high-density (HDPE) options based on your specific needs. LDPE polybags offer a cost-effective solution for various food-grade industries, including meat processing, produce, and food and beverage packaging. On the other hand, MDPE and HDPE polybags, with their higher density and durability, are better suited for industries like mining and landscaping.

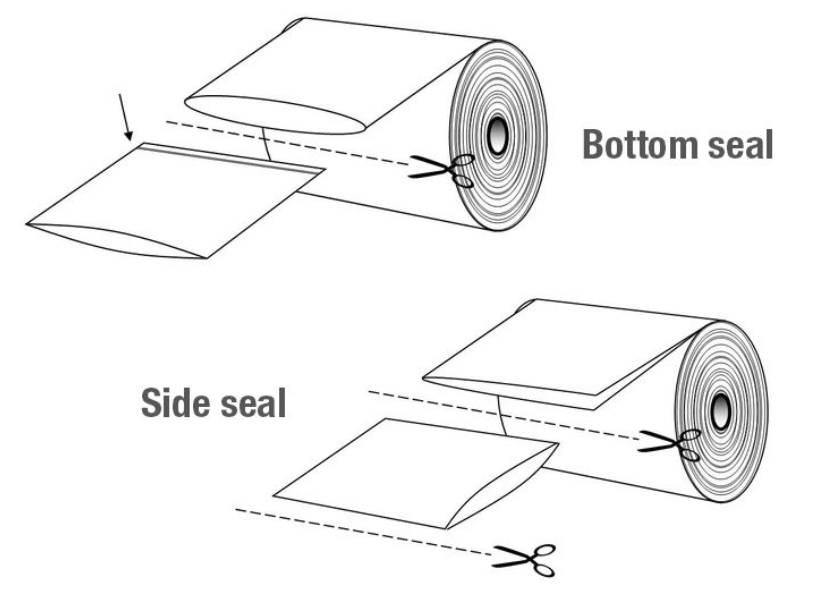

Our polybags are manufactured by converting extruded polytube on our bag machines. They can be provided either loose in cartons or on perforated rolls for convenient tear-off usage. Our custom manufacturing capabilities enable us to offer a wide array of design features, including gusseted bags, bottom seal plastic bags, side seal plastic bags, die-cut handles, and ventilation holes.

Side Seal Bags

Side seal bags typically feature a lighter gauge. They are created from folded polyethylene sheeting that are sealed or welded on each side using a hot blade. These side seal welds can be applied to flat or bottom gusseted bags.

Advantages:

- There is no seam on the bottom of the bag.

- The bag can incorporate a bottom gusset for added capacity or stability.

- Various features such as bag punches, holes, hang holes, and thumb notches can be easily applied as needed.

End Seal Bags

Bottom seal bags represent the ultimate heavy-duty and leakproof solution. They are produced by utilising high temperatures to seal the bottom of the bag, which is subsequently cut with a flying knife. These bags are tubular in design, with the seal positioned at the bottom width of the bag. Engineered to endure significant stress on both the seal and sides, end seal bags are an excellent choice for handling heavy materials.

The primary distinction between a side seal bag and an end seal bag lies in the manufacturing process. Bottom seal bags are typically crafted with a thicker gauge material, sealed using high temperatures, and then cut with a flying knife. On the other hand, lighter bags are commonly produced as side seal bags, where a hot blade seals and welds the sides of the bag.

Perforated Bags

Perforated bags are a versatile solution for various industrial needs, serving as box liners, pallet covers, drum liners, heavy-duty garbage bags, and more. At Formpack, we offer a wide selection of standard-sized bags, with the flexibility to customise solutions to meet specific requirements.

Backed by our HACCP certification, they ensure food safety standards are met, making them ideal for direct contact with food items.

Perforated Bag on rolls offer a convenient tear-off and dispensing. With pre-built perforations between each bag, they simplify preparation and streamline packaging processes, especially beneficial for high-volume operations. Utilising our perforated rolls enhances operational efficiency and convenience, making them a preferred choice for businesses aiming to optimise their packaging workflows.

Engineered for practicality, perforated bags feature a lightweight, easy-to-handle design, facilitating swift and efficient packaging processes. Whether in the food or dairy industry or other sectors, they offer a universal solution, enhancing productivity and operational efficiency. Their reliability and ease of use have made them a popular choice across various industries, meeting the evolving needs of modern businesses.

Pipeline Sleeves

Most modern metal pipes come equipped with corrosion-resistant coatings to stave off degradation from wear and tear, as well as day-to-day conditions. For pipes and fittings that are exposed to the weather elements, however, Formpack provides a selection of products designed to bolster resistance to corrosion and protect your products.

Pipeline sleeves represent the simplest, most cost-effective, and highly efficient method for safeguarding pipes. These sleeves create a non-bonded film covering that shields the metal from direct contact with the surrounding soil. By doing this, the plastic covers diminish the electrolytes available for fostering corrosion, leaving only the moisture present in the narrow space between the pipe and the polyethylene sleeve.

For optimal effectiveness, it’s imperative to use only the highest-quality sleevings. Formpack’s pipelines are crafted carefully in accordance with Australian standards, ensuring resistance to rot, biodegradation, and chemical decomposition.

Banana Slip Sheets & Carton Liners

Slip sheets serve as nearly invisible layers of packaging material placed between a pallet and a product load, or between layers within a product load. These sheets offer abrasion protection and are primarily used to keep products clean.

Banana box liners present a straightforward, economical solution to safeguarding fruit and preserving its quality during transportation. Customised for any box size and engineered with durable materials to resist tearing, these plastic liners keep your products intact for a longer period and help prevent food wastage.

Formpack’s slip sheets and carton liners are ideal for diverse settings such as grocery stores, farmer’s markets, and restaurants, able to cater to a wide range of applications. Available in various sizes, they effortlessly accommodate an array of products, ensuring versatility and convenience for users.

Dairy Industry

Milk and dairy products are packaged using a variety of materials, with the choice influenced by several factors including the type of product, processing and storage conditions, handling requirements, and intended use.

We specialise in manufacturing the plastic used for bottle packaging. Our customers operate state-of-the-art systems that minimise human interaction. Their machinery integrates robotic systems to handle our plastic rolls, transferring them onto the production line. Utilising artificial intelligence, the system identifies and inspects printed details on the bags, subsequently opening and filling them with newly manufactured bottles before sealing them. A robotic arm then accurately extracts and transfers the filled products to the subsequent conveyor belt, facilitating efficient shipment to farmers for filling.

Other Packaging

Formpack is dedicated to collaborating with you to develop a product that perfectly aligns with your requirements and budget. Recognising that not everyone is proficient in all facets of manufacturing, we are committed to providing assistance with integrity and expertise. Whether you’re seeking guidance on materials, design, or production processes, we’re here to support you every step of the way.

Contact Us

Want to get in touch to discuss our services and what we can do for your industry? You can call us by phone or email us directly with the following information.